| Metalco produces most of the

Steam Boiler Accessories needed for the complete construction of Steam Boiler Systems. |

||||||||||||||||||||||||||||||||||||||||

CONDENSATE TANK

|

||||||||||||||||||||||||||||||||||||||||

The

main features of such a Condensate tanks are:

|

|

|||||||||||||||||||||||||||||||||||||||

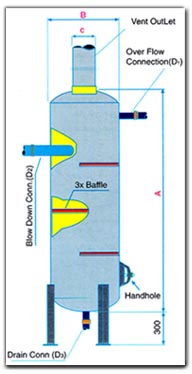

BLOW DOWN TANK When the Steam

Boiler is fully operated much precipitation, Hence, these impure extracted elements from the boiler may cause some nuisance and/or damage the sewage system at the location. This tank works on separating these foreign impurities through the bottom of the tank, and sends evaporated water through its vent outlets into the outside air. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

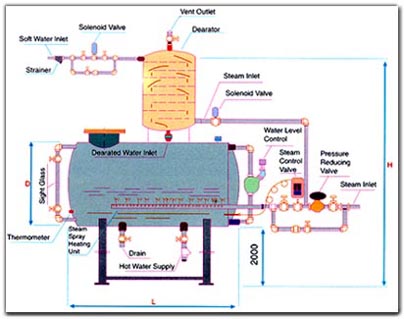

DEARATOR (CONDENSATE, FEED WATER TANK with DEARATOR) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| After water has been filtered by the "Water softener unit" for the purpose of providing the boiler with suitable water to produce steam free of impurities, this filtered water "Soft Water" will still have different harmful gases; Worst of which will be Oxygen and Carbon Dioxide. Thus, the best way of eliminating these gases from the feed water before it reaches the steam boiler is through a "Dearator". |  |

||||||||||||||||||||||||||||||||||||||||||||||||||||

| When water evaporates, it launches

Oxygen at very high speed causing minute wholes on the

surface of the metal that it bombards. As for the Carbon Dioxide, it forms carbonic acid which in turn has a negative effect over the boiler metals and could lead to " Corrosion ". The Dearator (as per the figure below) consists of Horizontal tank that heats water up to 104oC and frees Oxygen and Carbon Dioxide through the upper tank, whereas water and steam are sent to the opposite direction " Counter Current ". In this manner, evaporation and freeing of gases take place at the upper level of the tank "Tower- Ejector" and water is provided free of harmful gases. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| BURNERS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The

most suitable Burner type

to be chosen for any

steam boiler depends on " Fuel Consumption at Full Load ", and " Boiler Back Pressure Resistance " . Below are the relevant information needed to chose the right burner for each Steam Boiler: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||