|

| We

at Metalco do not spare the means or the efforts when it

comes to assuring Safety and Control Measures in our Steam Boilers. Control, Operation and Safety equipment and devices are chosen in accordance to top European standards and specifications that would insure the highest levels of Safety and Security when operating our Steam Boilers, and maintaining boilers operation efficiency at their maximum. Below are a summary of these safety and control instrument : |

|||

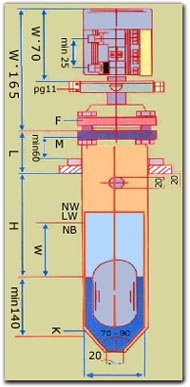

| "Water Level Regulator and

Limiter" The Boiler is fitted with two upper submerging Devices that comprises of two separate floaters as an extra water level safety and control device that operates under the German standard "DIN 40050". The "Water Level Regulator" works on switching the pump on and/or off when water level reaches the normal operating level. This device also works on disengaging and/or shutting-off the Burner when water level reaches below the normal operation levels. Further, if water level continues dropping below its normal levels, the "The Water Level Limiter" will disconnect the electric power supply and will operated the alarm bell when water level reaches its minimum. This device is very accurate in measuring the boiler’s water level, for the installed floaters in this device are surrounded by a special tube that would maintain the correct water level and would never subject the device to calcification or gather floating dirts like other conventional devices. "Pressure

Regulator and Limiter" |

|

|||

| The first device works

on controlling the

operation of first stage of the

burner, while the second controls the second stage of the burner. If the first and second devices should fail to operate for any reason, the third device will work on disconnecting the electric power supply and sounding the alarm bell when pressure level increases. Thus maintaining maximum boiler safety and control. "Water Gauge with

Valves and Reflection Glass" "Steam Valve" |

| "Blow

Down Valve" This is a quick open and shut valve "Quick Action Blow Down" that has a great impact on maintaining the cleanliness of the boiler and preventing precipitation and calcification on it base through the sudden high speed and velocity of the discharged water coming out. "Safety

Valve" "Feed

Water System" |

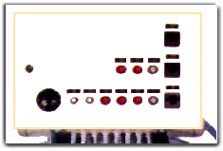

| "Electric

Control Panel" All of our Steam Boilers are fitted a unique Control-Panel box which insures that all equipment and Sequentially Controlled Program units are in full automatic operation. The boiler responds automatically, instantly and efficiently to any fluctuating steam demand – thus economizing the fuel consumption at a lowest possible rate, and exactly proportionate to actual steam consumption. |

|

| The Control Panel contains all the electric switches and panels necessary for operating, controlling, and quickly locate any malfunctions, in addition to other special control keys and switches necessary needed to conduct periodic and routine check and maintenance on the boiler. All the electric switches, panels, and keys are from well-known international brands, and the "Panel Box" is made in accordance to German standards and specs "DIN VDE Standard 0116". |